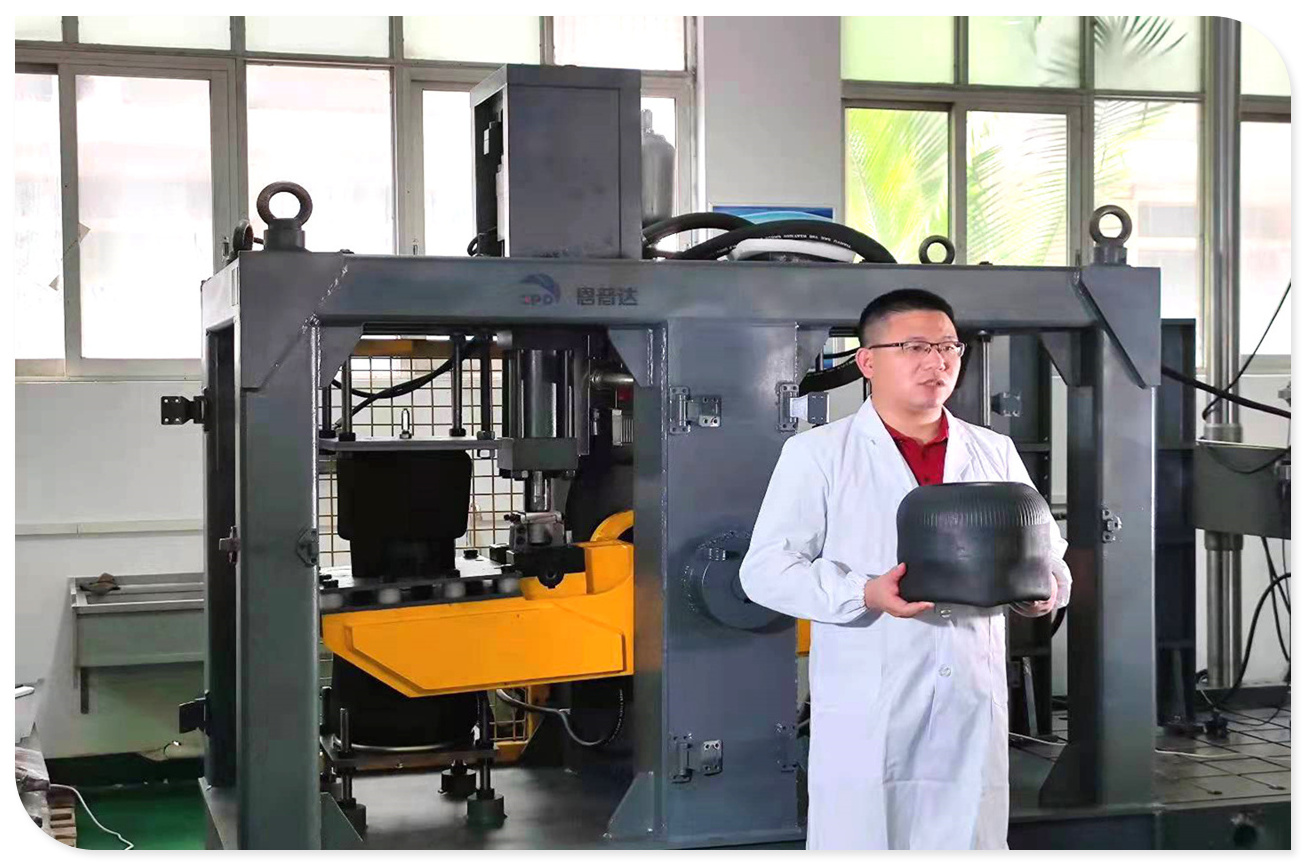

Electro-hydraulic servo pressure testing machine

Product function and purpose

It is a dedicated machine for flattening composite steel pipes, seamless steel pipes, carbon steel pipes, alloy pipes, stainless steel pipes and other steel pipes. The fully digital measurement and control system can realize the two test methods of prescribed distance flattening and closed flattening to realize closed-loop control of force, displacement and deformation. The test software works in the Windows Chinese environment, with powerful data processing functions, and the test conditions and test results are automatically saved. , display and print. The test process is all under computer control. The test machine is an ideal and cost-effective test system for scientific research institutes, metallurgical construction, national defense industry, colleges and universities, machinery manufacturing, transportation and other industries.

Product specifications

|

Testing machine type |

EH-8305 four-post | EH-8605 four posts | EH-8106

Six posts |

EH-8206

Six posts |

EH-8506

Six posts |

| Maximum load (kN) | 300 | 600 | 1000 | 2000 | 5000 |

| Load accuracy | Better than the indicated value ±1%, ±0.5% | ||||

| Test parameter

measurement range |

1 ~ 100%FS (full scale), which can be extended to 0.4 ~ 100%FS | 2 ~ 100%FS (full

scale) |

|||

| Displacement and deformation

accuracy |

Better than the indicated value ±1%, ±0.5% |

||||

| Speed range (mm/min) | 0.01 to 50(expandable to 100) | ||||

| Test parameter

resolution |

Load, deformation of the whole process is not graded and the resolution is unchanged ±1/350000FS (full scale) |

||||

| Tensile/compression test space (mm) |

620/550 |

690/620 |

620/580 |

700/600 |

650/600 |

| Test width of left and right posts (mm) | 500 | 570 | 600 | 600 | 650 |

| Round specimen

holding diameter (mm) |

Φ10 to 32 |

Φ13 to 40 |

Φ14 ~ 45 |

Φ20 to 70 | Φ20 to 80 |

| Plate specimen

holding thickness (mm) |

0 to 15 |

0 to 30 |

0 ~ 40 |

0 ~ 50 |

0 to 80 |

| Motor power (kW) |

1.50 |

2.20 |

2.20 |

5.50 |

11.0 |

| Overall dimensions (L x W x H) mm | 800 * 500 * 1950 | 950 * 630 * 2260 | 980 * 650 * 2220 |

1200 * 850 * 2900 |

1350 *

950 * 3200 |

| Weight of the engine (Kg) | 2000 | 2500 | 3300 | 5500 | 10000 |

Testing machine standard

1. It meets the requirements of GB / t2611-2007 general technical requirements for testing machines, GB / t16826-2008 electrohydraulic servo universal testing machines and JB / t9379-2002 technical conditions for tension compression fatigue testing machines;

2. Meet GB / t3075-2008 metal axial fatigue test method, GB / t228-2010 metallic materials tensile test method at room temperature, etc;

3. It is applicable to GB, JIS, ASTM, DIN and other standards.

盐雾试验箱2_副本11-300x300.png)