Air spring fatigue test bench

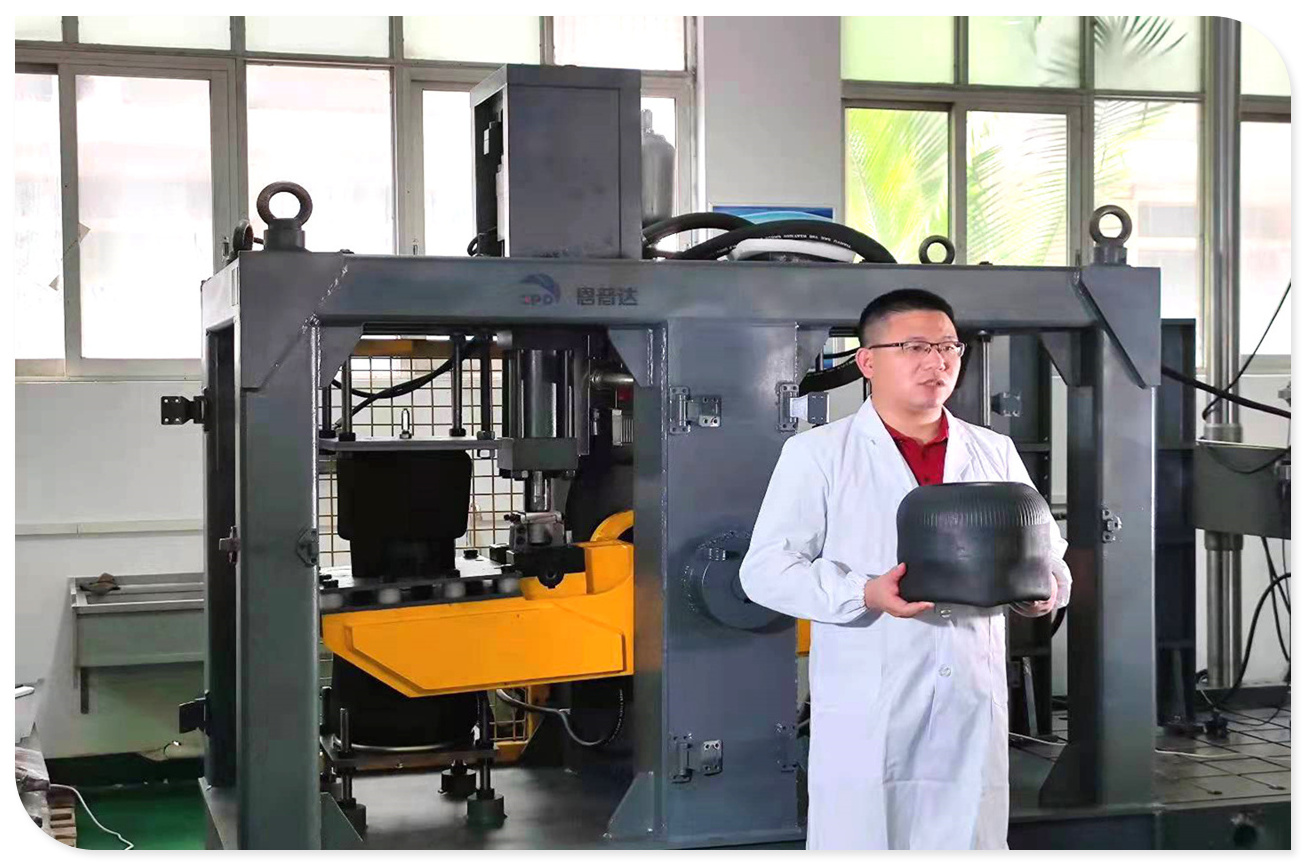

Product function and purpose

It is mainly used to test the dynamic and static mechanical properties of various materials, parts, elastomers, shock absorbers and components. It can perform tensile, compression, bending, low and high cycle fatigue, crack propagation, and fracture mechanics tests under sine wave, triangle wave, square wave, trapezoidal wave, and combined waveforms. It can also be equipped with environmental testing devices to complete environmental simulation tests at different temperatures.

Product specifications

| Maximum test force(KN) | 100 |

|

Load measurement range(KN) |

2 to 100 |

| Actuator stroke (mm) | Plus or minus 50 |

|

Relative error of dynamic indication value |

Plus or minus 1.0% |

| Test waveform | Sine wave |

| Host response

frequency range (Hz) |

0.01 to 5 |

| Trial count |

1 x 10' ~ 1 x 10。 times (optional) |

| Control method | PIDF control mode is adopted

to achieve closed loop control of force, displacement, deformation and other variables |

| Protection function | Displacement, load, fatigue times set

automatic stop protection |

Testing machine standard

GB/T 13061-2017 Technical specifications for air springs for commercial vehicle air suspensions

TB/T2841-2010 Railway vehicle air spring

盐雾试验箱2_副本11-300x300.png)