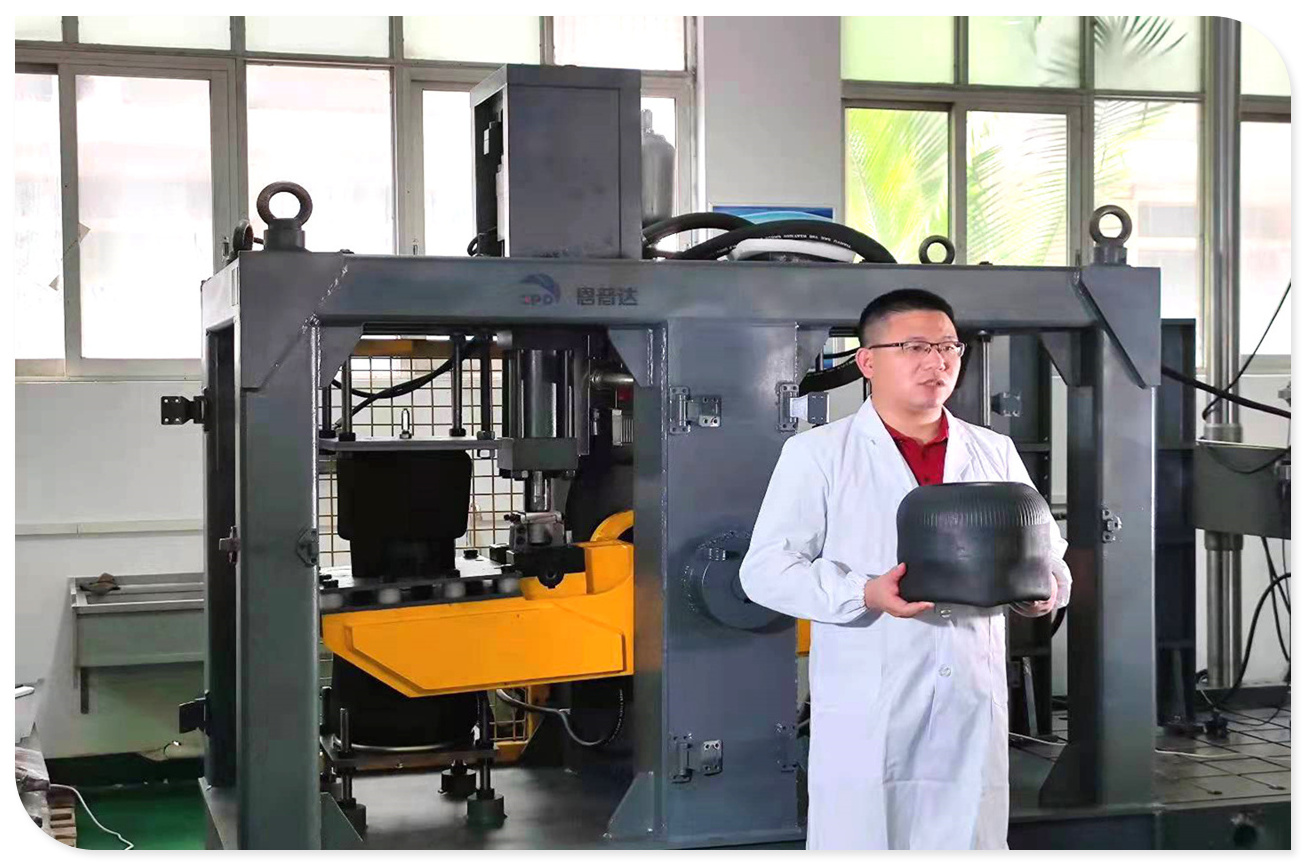

Bending fatigue testing machine

Performance features / advantages

1. Using electronic servo and DDR torque motor drive technology, it has the advantages of high efficiency, long life, low noise and maintenance-free;

2. The testing machine adopts a "horizontal floor-standing structure" with good dynamic stability, and the loading and unloading of the test bench is convenient, random, safe and reliable;

3. The parameters required for different tests, such as torque, frequency, rotation angle, etc., can be set and displayed on the computer screen, and the progress of the test can also be called and queried at any time;

4. User operation interface: The test software can be operated under the Windows system, and the microcomputer system can complete test settings, working status control, data collection, and calculation processing. Simple and reliable human-computer interaction interface and data processing interface, complete the different experimental requirements selected by the user, display and print the test results;

5. Open data structure: Both result parameters and process data allow users to call them randomly, which is very convenient for scientific research and teaching;

6. Multiple protection measures: When the sample is damaged, the tooling is broken, or the equipment fails, the test will automatically stop and alarm. During the automatic control test, the testing machine has overload, over-angle, over-temperature, electronic limit protection, over-current, and over-current protection. Various electrical protections for voltage and other power links, software partial overload, mechanical mandatory safety limit protection, etc.

Product specifications

| Testing

machine type |

EH-6103 | EH-6303

EH-6503 |

EH-6104 | EH-6204

EH-6304 |

EH-6504 | ||||

| Maximum test force |

±1000N or less |

±3000N

±5000N |

±10KN | ±20KN

±30KN |

±50KN | ||||

| Testfrequency | 0.01 to 20Hz | ||||||||

| Number offatigue lives | Set any Settings 0 to 10 times | ||||||||

| Actuator travel (mm) | ±50, ±75, ±100, ±150 and custom | ||||||||

| Test loading waveforms | Sine wave, triangular wave, square wave, oblique wave, trapezoid wave, combined custom waveform, etc | ||||||||

| Measuring

criteri a Accura cy |

Load | Better than the indicated value ±1%, ±0.5%(static); Better than indicating value ±2%(dynamic) | |||||||

| Morphin g | Better than indicated value ±1%, ±0.5%(static); Better than indicating value ±2%(dynamic) | ||||||||

| Displac ement | Better than the indicated value ±1%, ±0.5% | ||||||||

| Test parameter

measurement range |

1 ~ 100%FS(full scale), which can be extended to 0.4 ~ 100%FS | ||||||||

| Test width(mm) | 400mm | 500mm | |||||||

| Test space(mm) | Three 500mm(without jig) | =600mm(without fixture | |||||||

| Motor power | 1.0 kW | 2.0 kW | 5.0 kW | ||||||

Testing machine standard

1. It meets the requirements of GB / t2611-2007 general technical requirements for testing machines, GB / t16826-2008 electrohydraulic servo universal testing machines and JB / t9379-2002 technical conditions for tension compression fatigue testing machines;

2. Meet GB / t3075-2008 metal axial fatigue test method, GB / t228-2010 metallic materials tensile test method at room temperature, etc;

3. It is applicable to GB, JIS, ASTM, DIN and other standards.

电子疲劳试验机台式2_副本1-300x300.jpg)