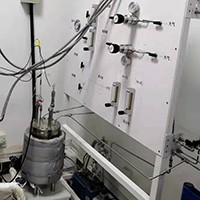

Slow strain rate stress corrosion tester

We not only provide standardized machines, but also customize machines and LOGO according to customer requirements. Please tell us your requirements and we will try our best to meet your needs.

Please provide the test standard you need to our company, our company will help you customize the test machine that meets the test standard you need

1. It is manufactured according to GB / t2611-2007 general technical conditions for testing machines and GB / T 16491-2008 electronic universal testing machines;

2. Verification and acceptance shall be carried out according to GB / t12160-2002 "provisions for extensometers for uniaxial test" and GB / t16825-2008 "inspection of tensile testing machines";

3. It is applicable to GB, JIS, ASTM, DIN and other standards.

| Model of testing machine | EH-5504F | ||||||

| Testing machine force value measurement accuracy | Level 0.5 | ||||||

| Test force measurement accuracy | Within ±0.5% of the indicated value | ||||||

| Test force measurement range | 200N~50KN | ||||||

| Test force indication resolution | 1/350000 of the maximum test force, no division and the same resolution in the whole process | ||||||

| Deformation measurement range | 0.4%-100%FS | ||||||

| Speed range(mm/min) | 0.001~500 (Scalable to 1000) | ||||||

| Resolution of test parameters | The load and deformation are not graded and the resolution remains unchanged ±1/350000FS (full scale) | ||||||

| Test space(mm) | 800 | ||||||

| Effective width(mm) | 560 | ||||||

| Power Supply | 220V±10% | ||||||

| Overall dimensions of main engine (length× width× height) | 1110×600×2220 mm (reference size) | ||||||

| Main engine weight(Kg) | about 600 kg | ||||||

| Tensile speed range of slow strain rate test: stepless adjustment between 1~1×10-6mm/s (achieved by two-stage deceleration) | |||||||

| Remarks: The company reserves the right to upgrade the instrument without any notice after the update, please ask for details when consulting. | |||||||