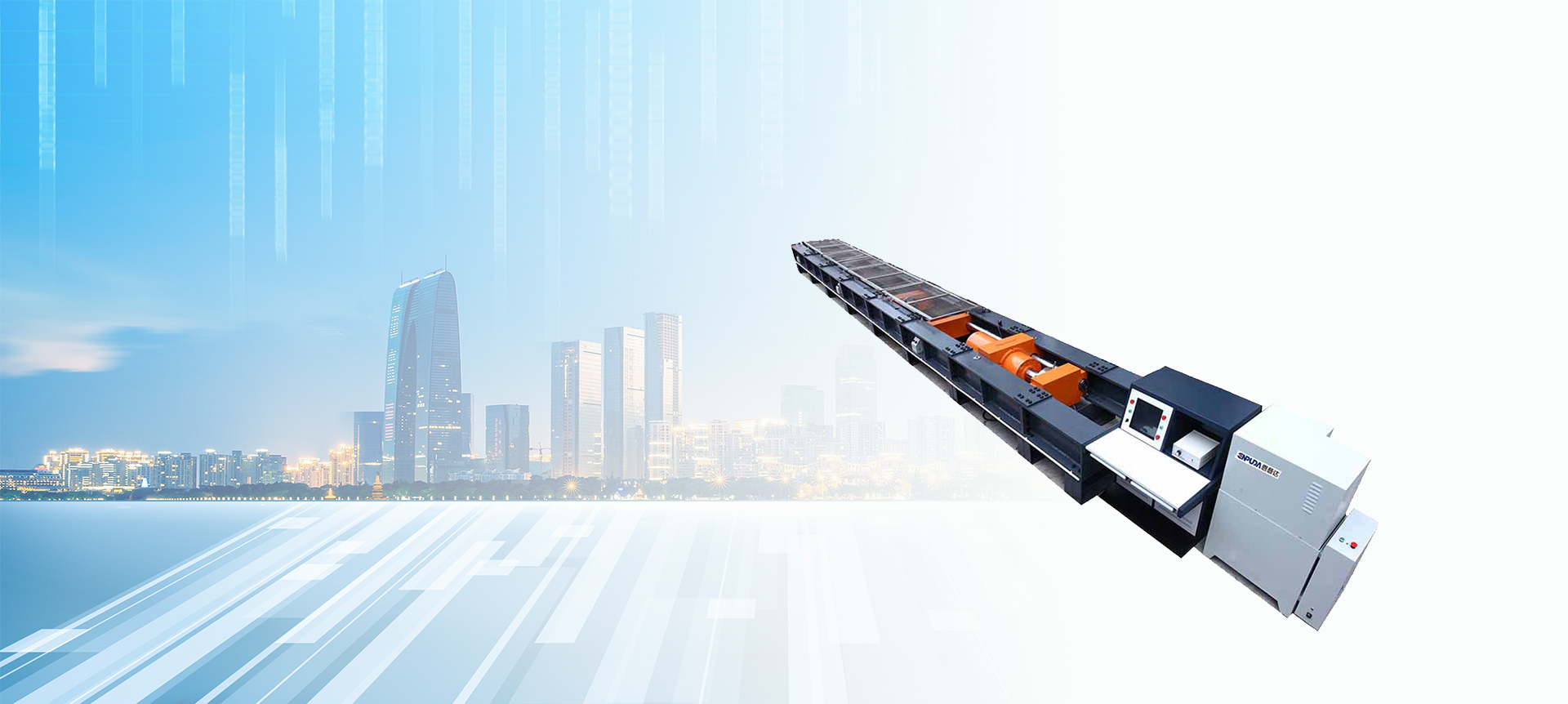

18 Years Factory Tensile Test Of High Carbon Steel - Electro hydraulic servo horizontal tensile testing machine – Enpuda

18 Years Factory Tensile Test Of High Carbon Steel - Electro hydraulic servo horizontal tensile testing machine – Enpuda Detail:

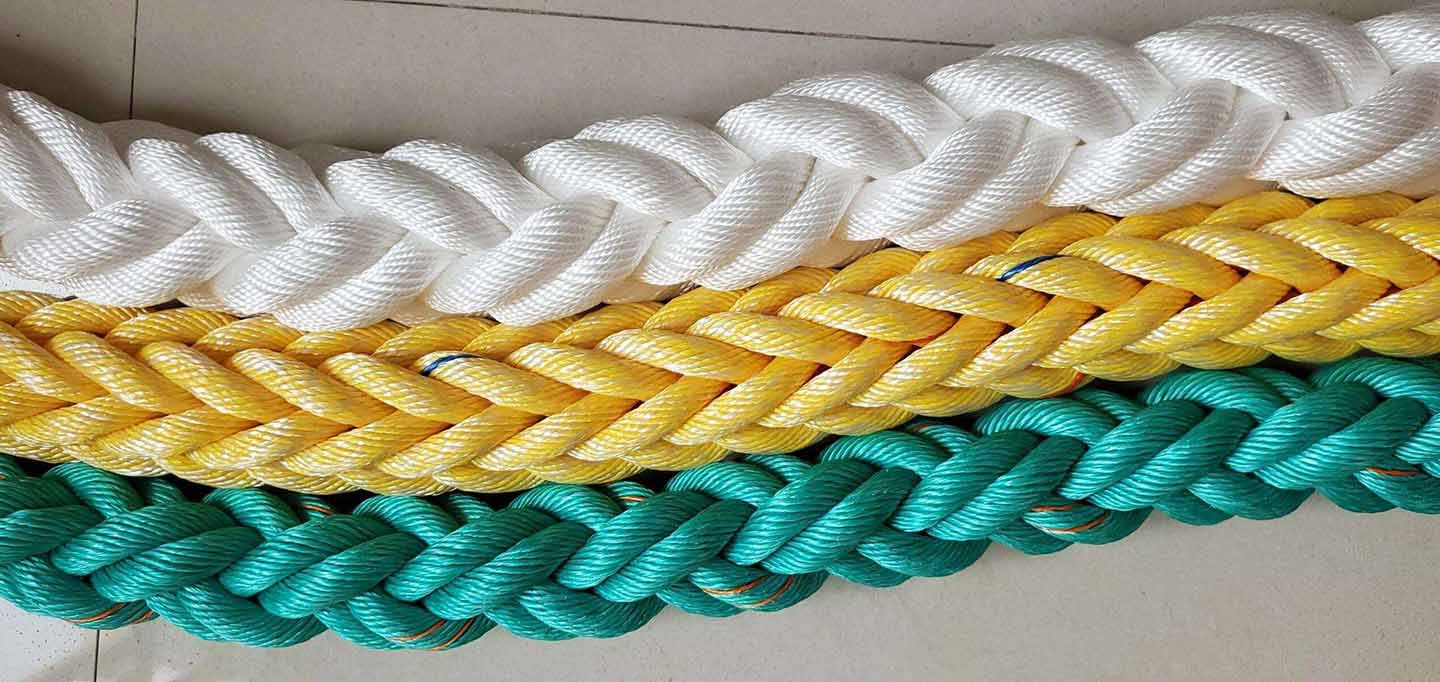

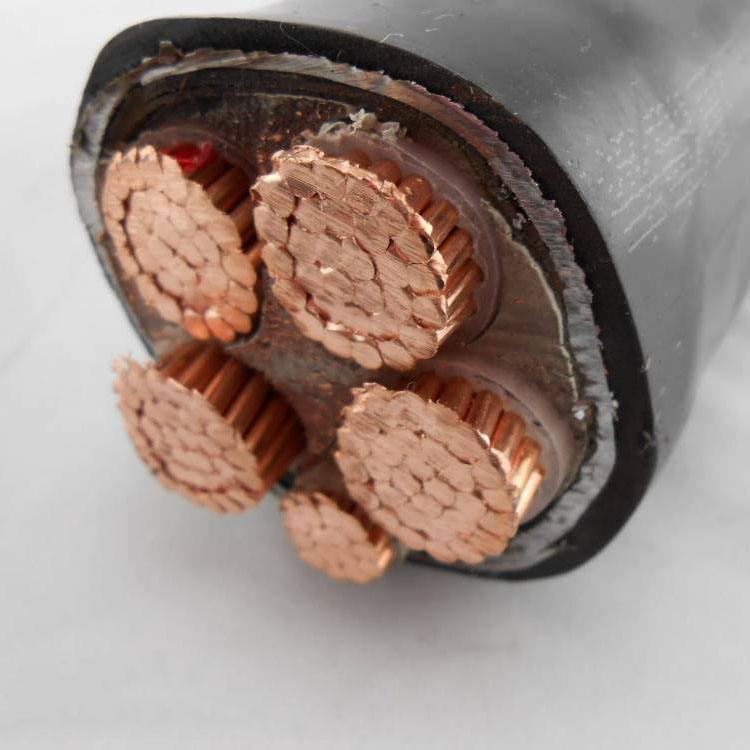

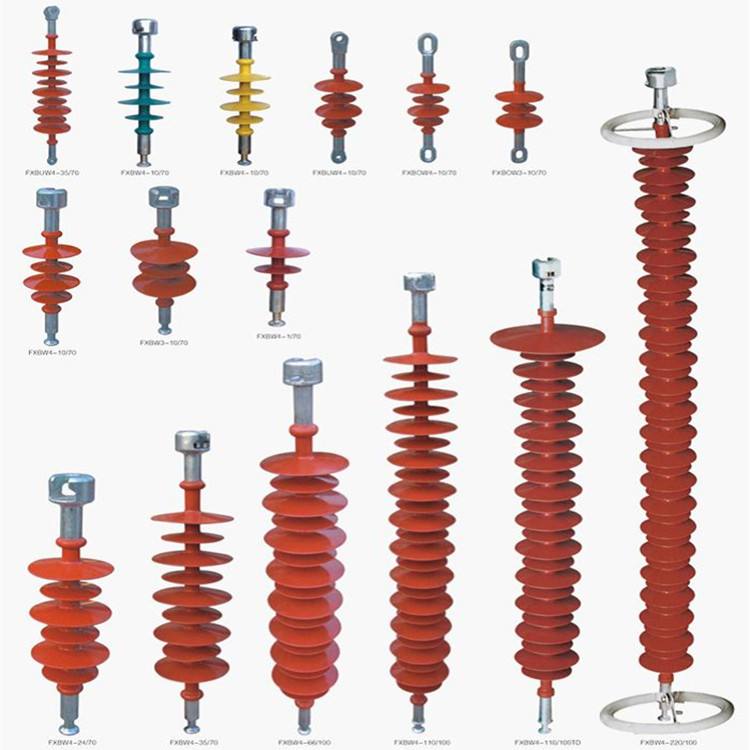

APPLICATION AREA

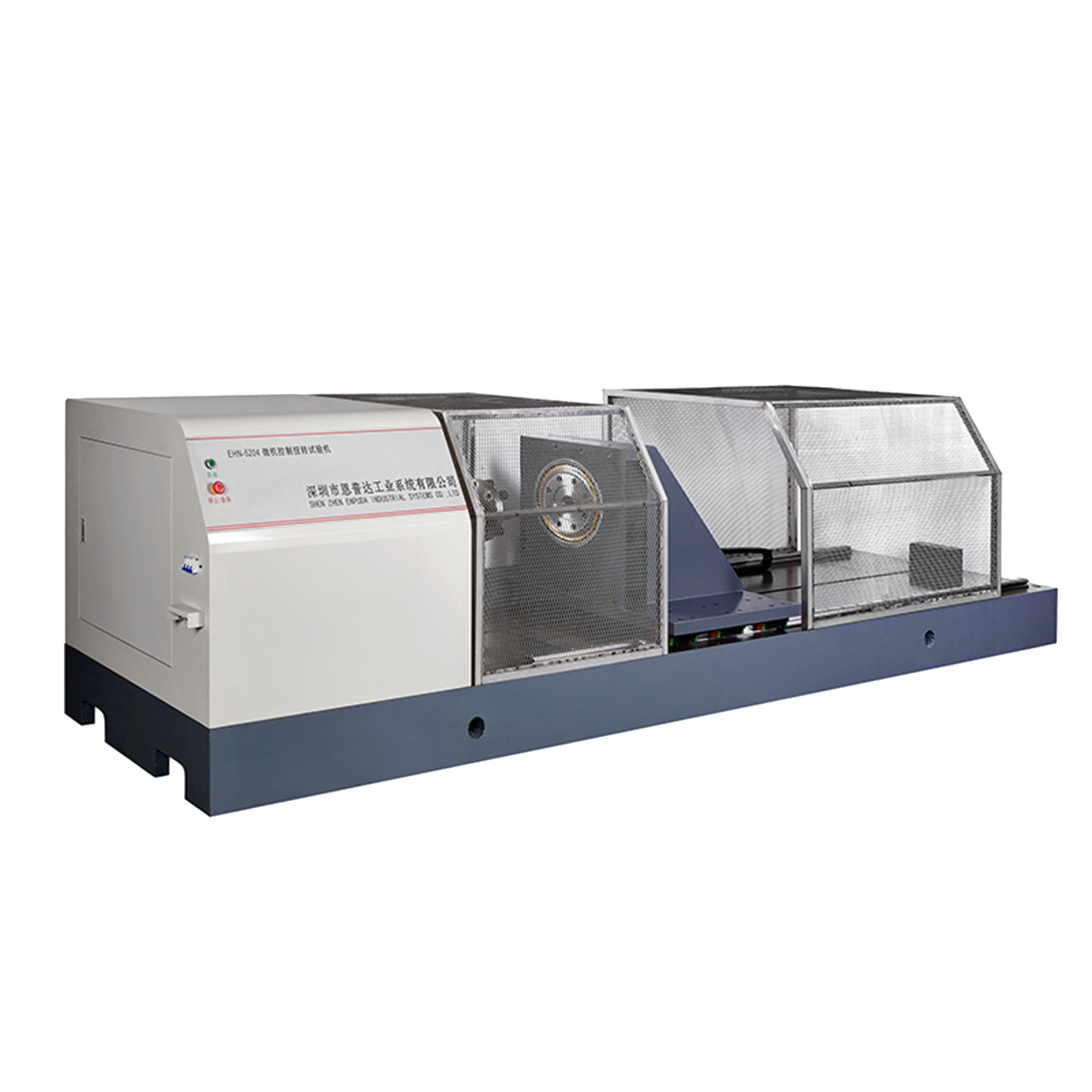

Electro-hydraulic servo horizontal tensile testing machine is mainly used for testing the force and tensile strength are tested. of steel wire ropes, power fittings, overhead wires, cables, wires and cables, insulators, grids, electric porcelain bottles and anchor chains.

Enpuda electro-hydraulic servo horizontal tensile testing machine is equipped with the latest remote module: it can realize the real-time operation and monitoring data of the remote computer terminal and mobile terminal of the testing machine, and has the function of networked remote automatic diagnosis after-sales service, which can solve the user effectively and without delay need.

Adopt advanced electronic technology, hydraulic loading computer for data collection and processing; powerful test software function has curve data storage and curve amplification functions, equipped with data interface for easy analysis.

Control mode: PID closed-loop control of force, displacement and deformation, and can realize smooth and disturbance-free switching of any control mode.

Open data structure: Both result parameters and process data allow users to call randomly, which is very convenient for scientific research and teaching. It is an ideal cost-effective horizontal tension system for scientific research institutes, metallurgical construction, national defense industry, colleges and universities, aerospace, rail transit and other industries.

Testing standard

Performance features / advantages

| 1. The key parts are international brands: DOLI controller in Germany, MOOG servo valve in the United States, Japan NACHI oil pump, |

| 2. The main engine of the testing machine adopts horizontal split structure. The cylinder ejection type produces tensile force through the reaction frame. The space is manually adjusted and the bolt is fixed. |

| 3. The system has high response speed, high control precision, strong anti pollution ability and high reliability. |

| 4. Safety protection function of testing machine. |

| 5. Control system and hydraulic system overload protection, in the non automatic shift state, when the test force exceeds 5% of the maximum test force of each gear, it will automatically stop loading and unloading. |

| 6. Mobile beam and oil cylinder limit position protection; |

| 7. Motor overheating and circuit short circuit protection; |

| 8. Oil temperature protection, oil circuit blockage protection; |

| 9. The safety net cover protects the specimen during tensile test, which is safe and beautiful; |

| 10. Automatic shutdown protection at the end of the test; |

| 11. With automatic loading function, the test load, loading speed, and pressure holding time can be adjusted |

According to the standard

| 1. Meet the requirements of GB/T2611-2007 “General Technical Requirements for Testing Machines”, GB/T16826-2008 “Electro-hydraulic Servo Universal Testing Machines” |

| 2. Meet GB/T3075-2008 “Metal Axial Fatigue Test Method”, GB/T228-2010 “Metal Material Room Temperature Tensile Test Method” and other standards; |

| 3. It is suitable for GB, JIS, ASTM, DIN and other standards. |

Key Parts

1. Optional German DOLI company EDC-I52 fully digital servo controller

2. Use American Interface high-precision dynamic force sensor

3. American MOOG servo valve

4. American MTS magnetostrictive displacement sensor

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for 18 Years Factory Tensile Test Of High Carbon Steel - Electro hydraulic servo horizontal tensile testing machine – Enpuda , The product will supply to all over the world, such as: Paris, Pakistan, Czech, Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.